State-Of-The-Art Mag Drive Technology.

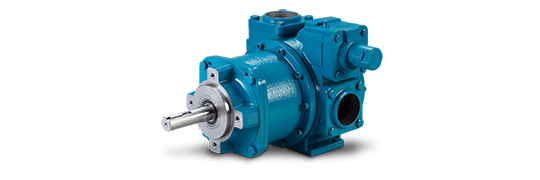

Mag drive gear pumps are engineered to prevent leakage of corrosive and hazardous fluids by eliminating the weak point for containing liquid within the pump, the seals for the drive mechanism. Standard internal and external gear pumps require a gear shaft to penetrate the pump housing and attach to a motor. Seals around the gear shaft bushing are meant to hold in the liquid, but they can weaken and leak, particularly if the liquid is highly corrosive.

In a mag drive gear pump, the gears that pump the liquid are entirely enclosed in the pump casing. Rather than a gear shaft connecting to a motor outside the casing, electro-magnetic forces turn the gears to create the pumping action. Mag drive pumps are available in a variety of standard and custom designs.

Anderson Process partners with trusted mag drive pump manufacturers — includingBlackmer,Liquiflo, andTuthill— to offer a large selection of positive displacement magnetically driven pumps for nearly any industrial process application.